Engineering Consulting

XFlow specializes in fluid mechanics and machine design for renewable energy systems with a focus on reducing cost and increasing efficiency. A summary of our areas of expertise can be found below:

Aerodynamic / Hydrodynamic

Visualization of vorticity shed off of a vertical-axis wind turbine simulated in OLAF.

XFlow’s engineers are world-class experts in the aerodynamics / hydrodynamics of energy extraction systems. XFlow engineers are fluent in a number of third party computational tools to optimize rotor efficiency in addition to operating a library of internally developed software’s for rotor and wind farm optimization.

Structural design

Structural design is often the most time intensive aspect of designing a new energy system. XFlow offers support with ultimate and fatigue load design, specification of fasteners and welds, composite design, and design for manufacture. Where relevant, XFlow designs to the relevant national or international standard, such as Eurocode 3 and IEC 61400 for wind systems. XFlow uses Solidworks CAD and FEA tools in addition to internally developed software to efficiently conduct structural design to your specifications.

Electrical systems and Control

The electrical system of a renewable energy system is where the magic happens. We often consult with customers intrested in our power conversion and/or control systems to demonstrate its value prior to them adopting this system for their product. Contact us to learn more about this system and if it would be a good fit for your application.

Contact Us Now for Engineering Consulting!

Prototyping

XFlow works with customers to design and fabricate prototypes and test plans to address key technical risks and to demonstrate the efficiency and/or levelized cost of energy of their renewable energy systems.

Utilizing XFlow’s in-house tools and leveraging our manufacturing partners, we can take any design from paper to the laboratory or field.

Testing

Wind tunnel and Field testing

XFlow co-founder Ben Strom, PhD, testing a plasma-actuator control scheme on a vertical-axis rotor

XFlow has extensive experience building, instrumenting, and testing scale-model turbines for field and wind-tunnel testing. XFlow has an 2.4 x 2.4 m open jet wind tunnel for test setup commissioning and troubleshooting. Typically final tests are performed at third-party facility, such as the University of Washington Kirsten Wind Tunnel, Florida International University Wall of Wind, or the Aerodyn Wind Tunnel.

XFlow has a large collection of six-axis load cells, torque cells, and strain gauge measurement equipment for measuring loads and mechanical performance of wind turbine rotors. Custom build PC-based data acquisition software can be rapidly created based on the requirements of a customers desired measurement campaign. XFlow has experience designing and executing field testing that complies with the relevant IEC 61400 standards.

Contact Us Now for Testing Services!

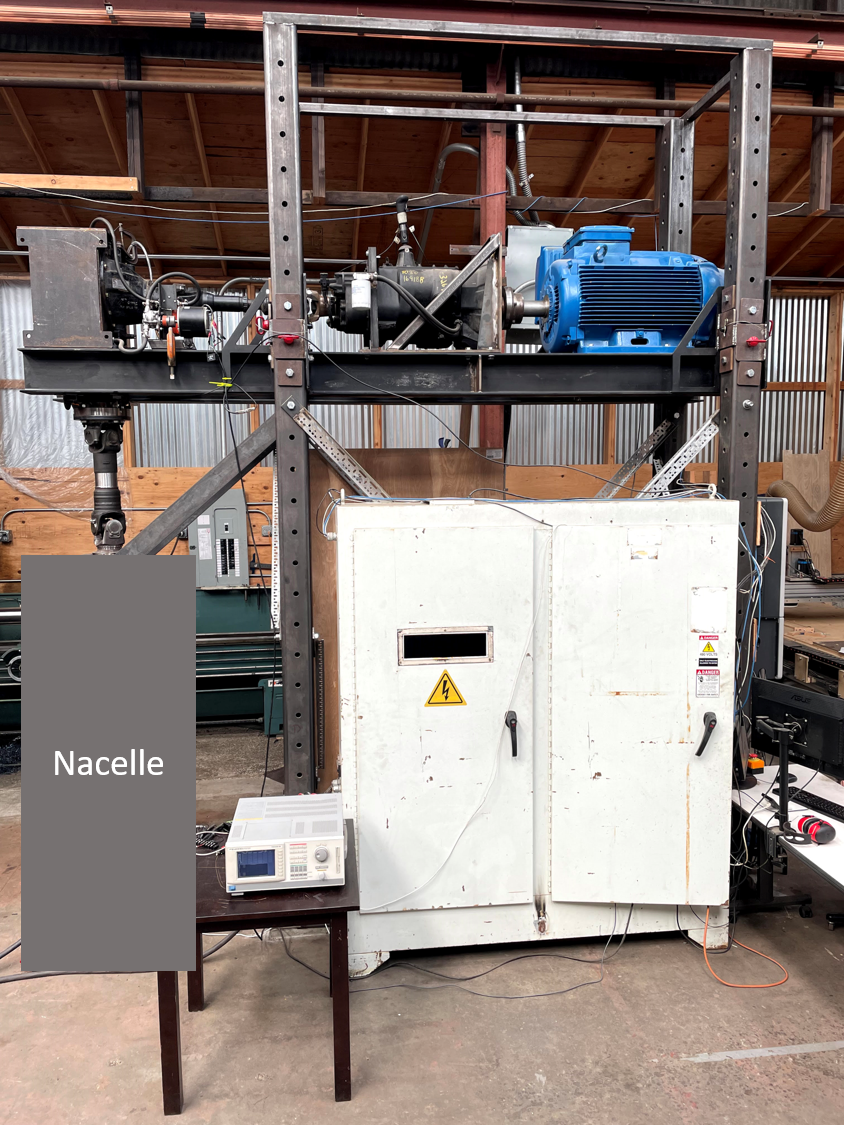

A vertically oriented nacelle being tested at XFlow’s 150 kW dyno facility.

Drivetrain Testing

XFlow’s 150 kW dyno facility is designed to de-risk renewable energy systems from the spindle (main shaft) to the grid before getting to the field. Our dynamometer is unique in that it can except both vertically and horizontally oriented nacelle. The dyno can be used to develop, validate, and or optimize components or system controls to maximize system efficiency and lifetime. The dyno can also be adapted to perform system or components accelerated life testing.

Features

A hardware-in-the-loop system allows for simulation of real and synthetic wind timeseries and fault events for controls testing

An 18-speed transmission driven by a 150 kW motor ensures the generation of the correct torque and speed range

An encoder and adjustable-range torque cell on the dyno output allows for precise control and measurement of the mechanical power input to the test drivetrain

A variety of electrical power measurement instrumentation is available to probe a system’s efficiency at multiple points along the path to the grid

Generators are available for electrical-system-only testing